When it comes to protecting your commercial building, few decisions are as important as choosing the right roofing system. Flat roofing has become the go-to choice for many business owners, and for good reason. These systems offer excellent durability, cost-effectiveness, and versatility that can meet the unique needs of your commercial property.

This comprehensive guide will walk you through everything you need to know about commercial flat roofing systems. We’ll cover:

- The different types of flat roofing systems available

- Popular materials and their benefits

- Cost considerations for your investment

🤔 What Are Commercial Flat Roofing Systems?

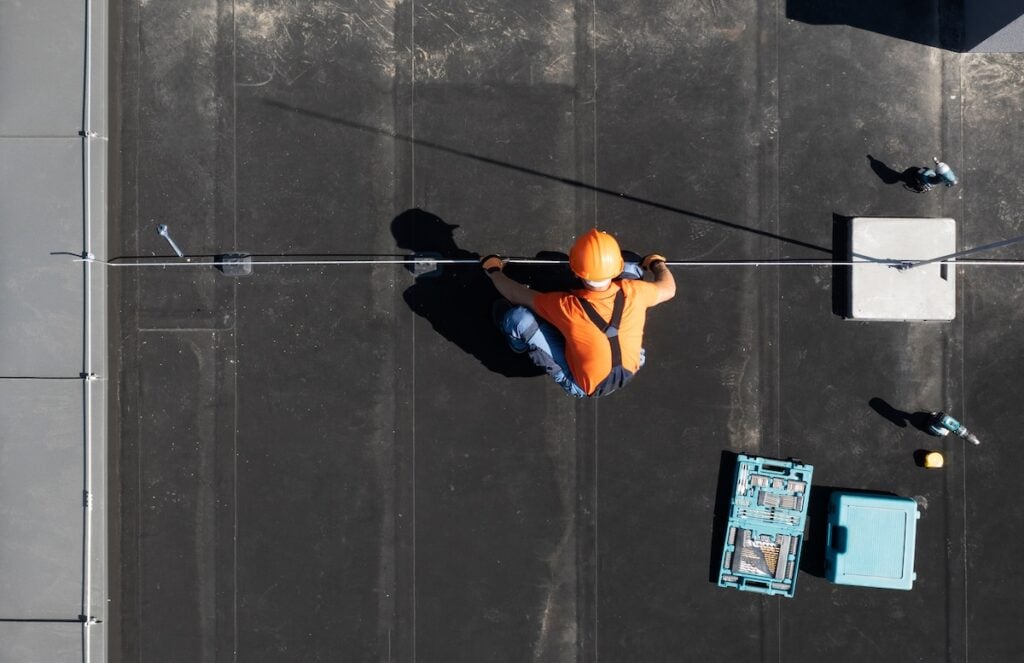

Commercial flat roofing systems are a popular choice for many building owners due to their practicality and cost-effectiveness. Unlike sloped roofs, flat roofs provide a level surface that can accommodate equipment like HVAC systems, solar panels, or even recreational spaces. These systems are typically made up of multiple layers designed to ensure water resistance, insulation, and durability. Understanding the basics of how these roofs function and the options available can help you determine which type will best suit your building’s needs while staying within your budget.

Key Advantages:

- Easier to install, maintain, and repair compared to traditional sloped roofs.

- Provide additional usable space for:

- HVAC equipment

- Solar panels

- Rooftop gardens

👉 5 Types of Commercial Flat Roofing Systems

Understanding the different types of flat roofing systems available will help you choose the best option for your commercial property. Each system has unique characteristics that make it suitable for different applications and budgets.

1. Built-Up Roofing (BUR)

Built-up roofing is one of the oldest and most reliable flat roofing systems. It consists of multiple layers of bitumen (asphalt or coal tar) alternated with reinforcing fabrics. The system is topped with a protective layer of gravel or mineral granules.

BUR systems are known for their exceptional durability and can last 20-30 years with proper maintenance. They provide excellent fire resistance and can withstand heavy foot traffic. However, they’re heavier than other systems and require skilled installation.

2. Modified Bitumen Roofing

Modified bitumen roofing combines the proven performance of built-up roofing with modern polymer technology. This system uses sheets of modified bitumen that are torch-applied, cold-adhered, or self-adhered to the roof deck.

The polymer modification makes these systems more flexible and resistant to cracking than traditional BUR. They’re easier to install and repair, making them a popular choice for many commercial applications. Modified bitumen roofs typically last 15-20 years.

3. Single-Ply Membrane Roofing

Single-ply membrane systems use large sheets of synthetic materials to create a waterproof barrier. The most common types are TPO (Thermoplastic Olefin), EPDM (Ethylene Propylene Diene Monomer), and PVC (Polyvinyl Chloride).

These systems are lightweight, energy-efficient, and relatively easy to install. They offer excellent resistance to UV rays, chemicals, and punctures. Single-ply membranes typically last 15-25 years and are available in various colors to meet energy efficiency requirements.

4. Spray Polyurethane Foam (SPF)

SPF roofing involves spraying liquid polyurethane foam directly onto the roof surface, where it expands and hardens to create a seamless, insulated barrier. The foam is then coated with a protective elastomeric coating.

This system provides excellent insulation properties and can conform to any roof shape. It’s particularly effective for irregular surfaces and can be applied over existing roofing materials. SPF systems can last 20-30 years with proper maintenance and recoating.

5. Liquid Applied Roofing

Liquid applied roofing systems use liquid polymers that cure to form a seamless membrane. These systems are ideal for roofs with complex shapes, numerous penetrations, or existing roof repairs.

The liquid application allows for easy installation around obstacles and creates a completely waterproof barrier. These systems are often used for maintenance and repair work but can also serve as primary roofing systems.

⭐️ Popular Commercial Flat Roofing Materials

The choice of roofing material significantly impacts the performance, longevity, and cost of your commercial flat roofing system. Let’s explore the most popular materials used in commercial flat roofing.

EPDM Rubber Roofing

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber membrane that has been used in commercial roofing for over 40 years. It’s known for its durability, flexibility, and resistance to extreme weather conditions.

EPDM roofs can withstand temperatures from -40°F to 300°F without cracking or becoming brittle. They’re also resistant to UV rays, ozone, and oxidation. Installation is relatively straightforward, and repairs are typically simple and cost-effective.

TPO Roofing

TPO (Thermoplastic Olefin) is a newer single-ply membrane that has gained popularity due to its energy efficiency and cost-effectiveness. TPO roofs are typically white or light-colored, reflecting heat and reducing cooling costs.

This material offers good resistance to UV rays, chemicals, and punctures. TPO seams are heat-welded, creating strong, permanent bonds. The material is also recyclable, making it an environmentally friendly choice.

PVC Roofing

PVC (Polyvinyl Chloride) roofing membranes are known for their chemical resistance and fire retardancy. They’re particularly suitable for buildings that house restaurants, manufacturing facilities, or other businesses that may have grease or chemical exposure.

PVC roofs offer excellent durability and can last 20-30 years. They’re available in various colors and provide good energy efficiency. The heat-welded seams create watertight joints that resist wind uplift.

Modified Bitumen

Modified bitumen materials combine traditional asphalt with polymers to create more flexible and durable roofing systems. The two main types are SBS (Styrene-Butadiene-Styrene) and APP (Atactic Polypropylene).

SBS-modified bitumen remains flexible in cold weather and is often called “rubber asphalt.” APP-modified bitumen is more plastic-like and provides excellent UV resistance. Both types can be installed using various methods, including torch application, hot asphalt, or cold adhesive.

💵 Cost Considerations for Commercial Flat Roofing

Understanding the costs associated with commercial flat roofing helps you budget effectively and make informed decisions about your roofing investment. Several factors influence the total cost of your roofing project.

Initial Installation Costs

The upfront cost of commercial flat roofing varies significantly based on the system type, materials, and building size. Generally, you can expect to pay between $5-15 per square foot for most commercial flat roofing systems.

EPDM systems are typically the most affordable option, ranging from $5-8 per square foot. TPO systems fall in the middle range at $6-10 per square foot. PVC and modified bitumen systems usually cost $7-12 per square foot. Premium systems like SPF or liquid applied membranes can range from $10-15 per square foot.

Long-Term Value and Maintenance Costs

While initial cost is important, consider the long-term value of your roofing investment. A higher-quality system with a longer lifespan may provide better value over time, even if it costs more upfront.

Regular maintenance is essential for all flat roofing systems. Budget for annual inspections, minor repairs, and periodic recoating or membrane replacement. Proper maintenance can extend your roof’s life significantly and prevent costly emergency repairs.

Factors Affecting Roofing Costs

Several factors can influence the total cost of your commercial flat roofing project:

Building size and complexity affect labor costs. Larger roofs typically have lower per-square-foot costs due to economies of scale. Complex roof shapes with many penetrations or obstacles increase installation time and costs.

Roof accessibility impacts installation costs. Roofs that are difficult to access may require special equipment or additional safety measures. The condition of the existing roof deck may require repairs or reinforcement before installing the new system.

Geographic location affects both material and labor costs. Areas with higher labor costs or challenging weather conditions may see increased pricing. Local building codes and permit requirements can also impact total project costs.

👨🔧 Trust Summit Roofing for Your Commercial Roofing Needs

At Summit Roofing & Restoration, we understand that your commercial flat roofing system is a critical investment in the long-term protection and efficiency of your building. With decades of experience, certified technicians skilled in all major roofing systems, and a commitment to using only top-quality materials, we deliver solutions tailored to your unique needs and budget.

From installation to maintenance and repair, we’re dedicated to providing exceptional service and ensuring your investment is built to last. Trust the team that prioritizes your business’s success and peace of mind. Contact Summit Roofing & Restoration today for a free consultation and estimate—let us help protect your building and your bottom line for years to come.